IoT’s Influence on Your Manufacturing Set-up

Posted By - Pony

Posted On - April 18, 2024

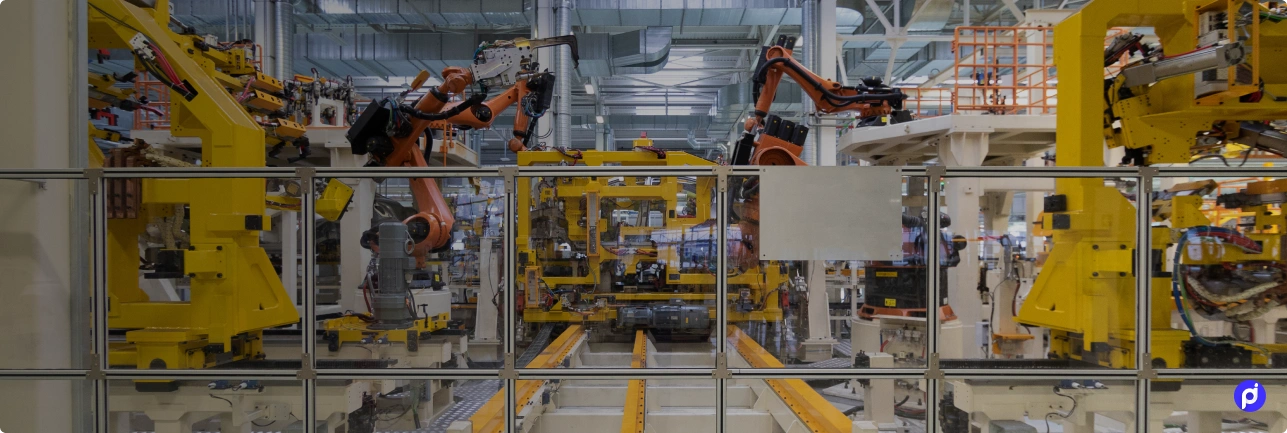

Many of you might think that technology cannot influence your operations. Are you sure about that? Without any proof it’s clear that you are carrying out the wrong idea. Here we are to correct your notions. Today, digital technologies are the weapons you should have to fight with your competitors. Changing customer wants and their desires to harness digital technologies have triggered the popularity of Internet of Things.

Let’s dig deep into IoT and its influence on your manufacturing set up.

Understanding IoT or Internet of Things

IoT is a series of objects implanted with software and sensors facilitating data transfer and connectivity of devices. Such devices can be your factory items. Did you wear any fitness tracking object like FitBit, then you will understand IoT better. And if you are still in doubt whether IoT can help you or not, then let me say a surprising statement. According to statistics about 75 billion devices will be associated with IoT till 2025.

Now, let us discuss the influence of the Internet of Things on your manufacturing set up.

Impact of IoT on Your Manufacturing Set Up

IoT technologies can be a turning point for your business. As a manufacturer you can make more informed decisions with the help of IoT. All your factory staff, irrespective of department, can detect failures and improve operations. Here we present some common influences of IoT.

1. Better Asset Tracking

Your factory contains a lot of valuable assets. Now, with IoT you won’t have to fear about assets getting damaged. Tracking is easily possible in any part of your manufacturing operations. If there is any chance of damage your managers will come to know immediately.

2. Enhanced Operations Management

IoT enabled sensors can keep a check on extreme temperatures, humidity and other harsh conditions. If there is any possibility of negative extremes, then you or your managers can easily detect it and get an alert.

3. Predictive Maintenance

Utilizing live data gathered from interconnected IoT devices enables the anticipation of potential flaws in tools and machinery, consequently mitigating downtime and bolstering overall productivity. So, this can stop your loss of output and you can save big bucks.

4. Better Machine utilization

When machines are connected to internet, you get an idea about how long it will work. Such data can help you to fix unplanned downtime.

5. Connecting Assets

Linking tools and devices enables seamless access to data from diverse remote resources through a single hub. This centralization allows for comprehensive examination and monitoring of assets, empowering greater control and oversight.

Winding Up

Machine monitoring, predictive maintenance and optimization of management are some impacts of IoT on your manufacturing. IoT will make your factory smart where all your assets will be interconnected with each other. Such assets can add value to your manufacturing. Hence, if you plan to digitize your operations you should keep an eye on custom manufacturing app developers. Connect with a Manufacturing application development company and take IoT software from them. This will put your factory on wheels.

Reference link: IoT devices installed base worldwide 2015-2025 | Statista

The FAQ’s:

FAQ 1. How does IoT benefit manufacturing operations?

IoT enhances manufacturing by enabling better asset tracking, enhanced operations management, predictive maintenance, improved machine utilization, and seamless connectivity of assets.

FAQ 2. Can IoT help in preventing asset damage in manufacturing facilities?

Yes, IoT allows for real-time tracking of valuable assets in manufacturing facilities. Managers can receive alerts if there’s a risk of damage, enabling proactive measures to be taken.

FAQ 3. What is predictive maintenance, and how does IoT facilitate it?

Predictive maintenance utilizes live data from IoT-connected devices to anticipate potential machinery flaws. By analyzing this data, downtime can be mitigated, resulting in increased productivity and cost savings.

FAQ 4. How does IoT contribute to better machine utilization in manufacturing?

IoT-enabled machines provide insights into their operational status and performance, allowing for proactive maintenance and scheduling to prevent unplanned downtime, thus optimizing machine utilization.

FAQ 5. How can manufacturers implement IoT in their operations?

To implement IoT, manufacturers can connect their existing machinery and equipment to the internet, integrate sensors for data collection, and utilize centralized platforms for monitoring and analysis. Partnering with a manufacturing application development company can help in developing customized IoT solutions tailored to specific needs.