Manufacturers do not want to settle for a simple application, they want something special. These are called custom manufacturing applications. Custom manufacturing applications are powered by technologies that attract manufacturing investors. Manufacturers always want an efficient production process which can be achieved with the skills present in custom manufacturing app developer. These developers use some prominent technologies which can make your business breathe easy.

Ways Smart Technologies are Making Custom Applications Lively:

1. AI for Smarter Decision-Making

Manufacturing is something beyond making goods and if your factory has a touch of artificial intelligence then you will be able to beat many other manufacturers. AI tools enable manufacturers to predict equipment failures, optimize production schedules, and reduce downtime. Custom manufacturing app developers are leveraging AI to design predictive analytics dashboards, and automation features that help businesses stay ahead of operational challenges.

2. IoT-Enabled Connectivity for Real-Time Monitoring

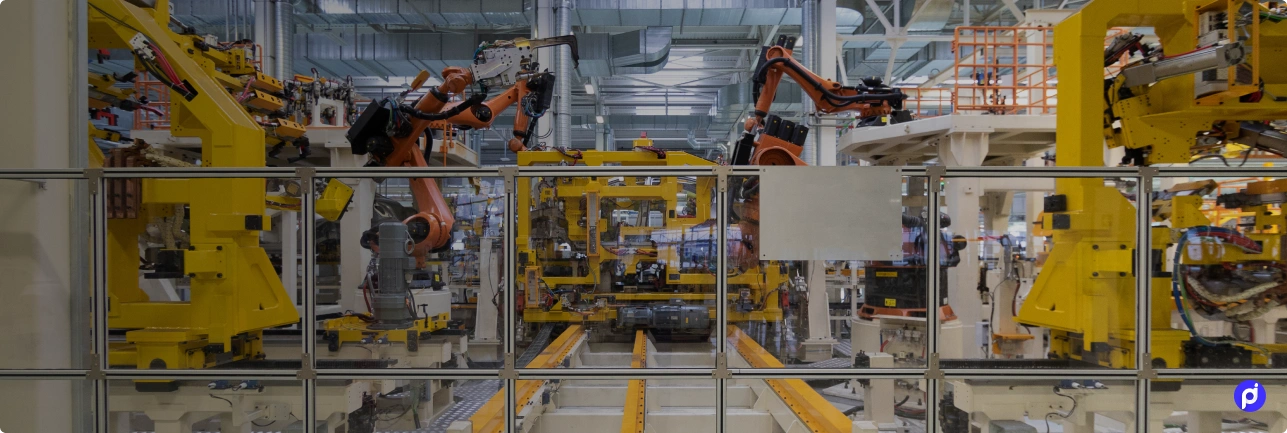

The Internet of Things (IoT) connects machines, devices, and systems in the manufacturing ecosystem. This connectivity allows real-time data collection and monitoring through custom apps. IoT-powered manufacturing apps provide instant visibility into factory operations, including equipment health, energy consumption, and production status.

Custom manufacturing app developers are building IoT-integrated solutions that enhance decision-making and operational efficiency by turning raw machine data into valuable insights.

3. Augmented and Virtual Reality

Sucess stories in manufacturing contains the idea of Augmented and Virtual reality. Custom manufacturing applications having the touch of this technology can make your machine maintenance easier. The technology is used by custom manufacturing app developers whose efforts can raise your productivity and remove unplanned downtime. Smart technologies like Augmented Reality (AR) and Virtual Reality (VR) are revolutionizing training and maintenance processes. Custom manufacturing apps equipped with AR and VR capabilities help workers visualize complex assembly instructions, troubleshoot machinery, and receive remote support.

4. Cloud Computing for Scalability and Data Management

Cloud computing plays a significant role in the success of custom manufacturing apps. By hosting apps in the cloud, manufacturers can access real-time data and collaborate across different locations. Additionally, cloud-based apps provide scalability, enabling companies to expand their operations without worrying about infrastructure constraints. Custom manufacturing app developers are increasingly adopting cloud technologies to ensure that their solutions are scalable, secure, and easy to maintain.

Final Thoughts

The manufacturing sector is getting much more modernized with popular technologies. These technologies are going to reshape the manufacturing pattern. Custom manufacturing app developers are filled with enthusiasm who want to make you adopt modernization. They always carry positive thoughts for the manufacturing industry and if you can use their expertise properly you will come to realize the potential of these technologies.

The FAQ’s:

FAQ 1. What are custom manufacturing applications, and why are they important?

Custom manufacturing applications are tailored software solutions designed to meet the specific needs of manufacturing businesses. These applications help optimize production processes, improve operational efficiency, and provide valuable insights through the integration of advanced technologies like AI, IoT, and cloud computing. By using custom solutions, manufacturers can gain a competitive edge in the market.

FAQ 2. How does AI benefit manufacturing operations through custom applications?

AI-powered custom manufacturing applications enable smarter decision-making by providing predictive analytics and automation features. They help manufacturers predict equipment failures, optimize production schedules, and reduce downtime. These tools ensure smoother operations and increased efficiency in the production process.

FAQ 3. What role does IoT play in custom manufacturing applications?

IoT (Internet of Things) connects machines, devices, and systems within the manufacturing ecosystem, enabling real-time data collection and monitoring. Custom manufacturing applications leverage IoT to provide instant visibility into factory operations, such as equipment health, energy consumption, and production status, empowering manufacturers to make informed decisions and improve efficiency.

FAQ 4. How can Augmented Reality (AR) and Virtual Reality (VR) improve manufacturing processes?

AR and VR technologies are transforming manufacturing by enhancing training and maintenance processes. Custom manufacturing applications equipped with these technologies help workers visualize complex assembly instructions, troubleshoot machinery, and receive remote support. This reduces unplanned downtime and improves productivity.

FAQ 5. Why is cloud computing important for custom manufacturing applications?

Cloud computing allows manufacturers to host their applications in a secure and scalable environment. This enables real-time data access and collaboration across multiple locations. Custom manufacturing app developers adopt cloud solutions to ensure scalability, secure data management, and easy maintenance, helping companies expand their operations without infrastructure constraints.